Precious plastic describe this well,

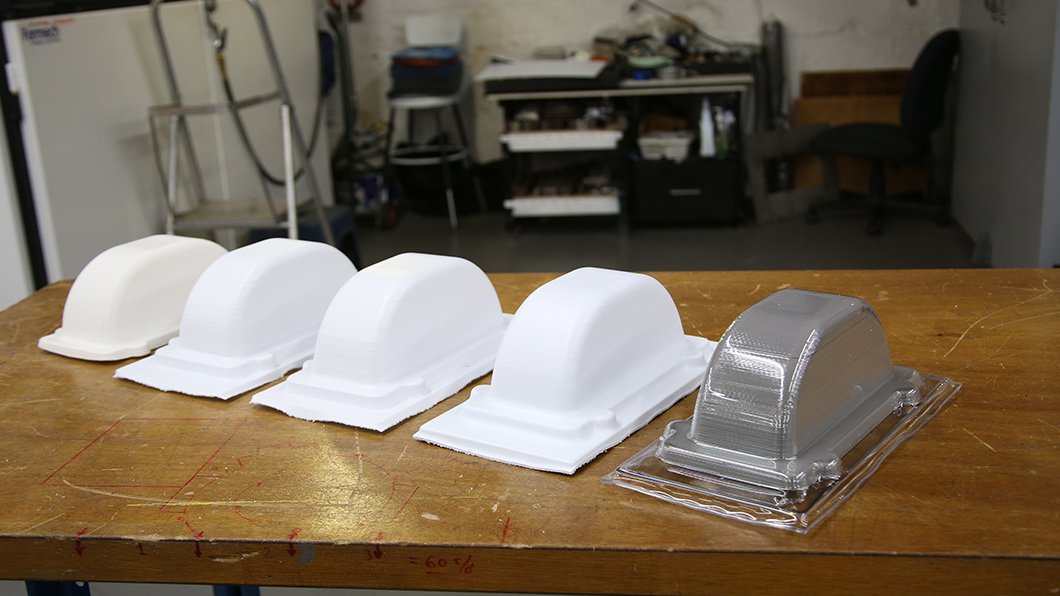

The word itself is derived from the Greek plastikos meaning “capable of being shaped or moulded” and refers to their malleability during manufacture that allows plastic to be cast, pressed or extruded into a variety of shapes—like films, fibres, plates, tubes, bottles and much more.

Plastics are synthetic chemicals extracted mainly from petroleum and made of hydrocarbons (chains of hydrogen and carbon atoms). Most plastics are polymers, long molecules made up of many repetitions of a basic molecule called a monomer and this structure makes plastic particularly durable and long lasting. Due to their relatively low cost, ease of manufacture and versatility, plastics are used in an enormous and expanding range of products, from shampoo bottles to space rockets.